TEMPEST ENGINEERING SPECIALIZES IN DESIGNING EXPLOSION PROOF (CLASS 1; DIV 2) CLASSIFIED CHILLERS

Process Cooling in Hazardous Environments COMPLIANCE TO CLASS 1 DIV. 2 C&D HAZARDOUS AREAS AS A STANDARD

COMBUSTION PRONE APPLICATIONS: OIL/GAS, CHEMICAL

OPEN DRIVE COMPRESSOR MOTORS OR SEMI HERMETIC

REMOTE MOUNTED OR PURGED CONTROL PANEL

COMPLIANCE AND COMPONENT SPECIFICATIONS BY REQUEST

WHAT CLASS, DIVISION, AND GROUP RATING ARE REQUIRED FOR YOUR CHILLER OR TCU?

2.5-TON AIR-COOLED, EXPLOSION PROOF, EXTRACTION CHILLER

Condensing Type: Air CooledTonnage: 2.5-TonsRefrigerant: R-507Chilling Temperature: -52°F EvapProcess Fluid: EthanolCompressor: Two-stage reciprocatingClassification: Class I, Division II with Z-purgeInstall Requirement: Outdoor Duty NEMA 4Controls: Watlow EZ-ZONE PM TIC

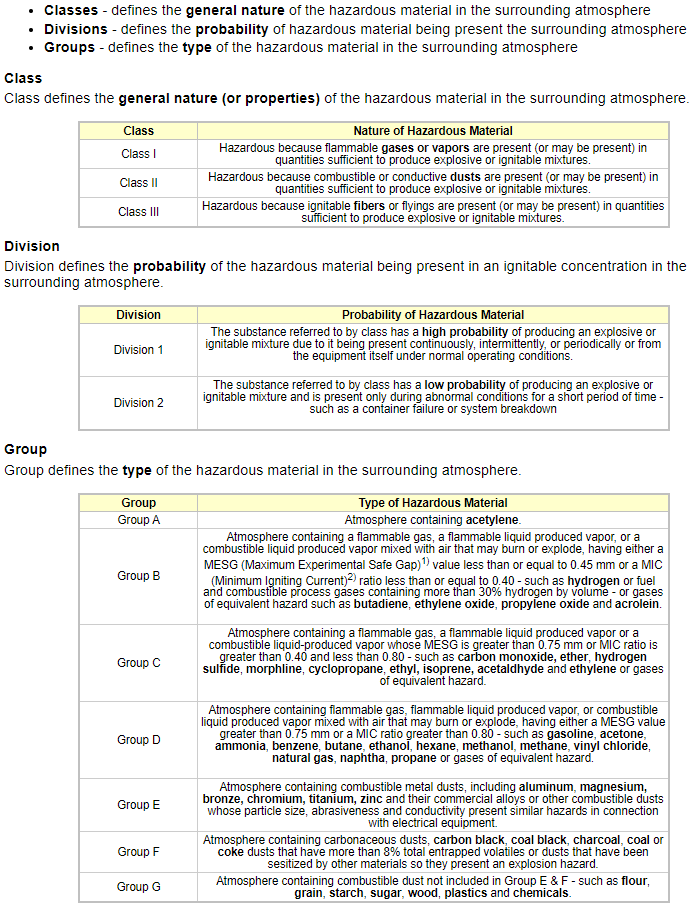

3-TON AIR-COOLED EXPLOSION PROOF BIOGAS STEAM CHILLER

Condensing Type: Air-CooledTonnage: 3-TonsRefrigerant: R-410AChilling Temperature: 30°FProcess Fluid: 30% Ethylene GlycolCompressor: Digital Scroll Hermetic CompressorClassification: Explosion Proof: Class 1; Div 2Evaporator: Direct Expansion Brazed PlateControls: DIN Watlow EZ Zone Temperature Indicating ControllerSkid Dimensions: 36”W x 102”L x 72”H

5-TON WATER-COOLED, EXPLOSION PROOF, EXTRACTION CHILLER

Condensing Type: Water CooledTonnage: 5-TonsRefrigerant: R-507Chilling Temperature: -50°FProcess Fluid: EthanolCompressor: Two-stage screwClassification: Class I, Division II

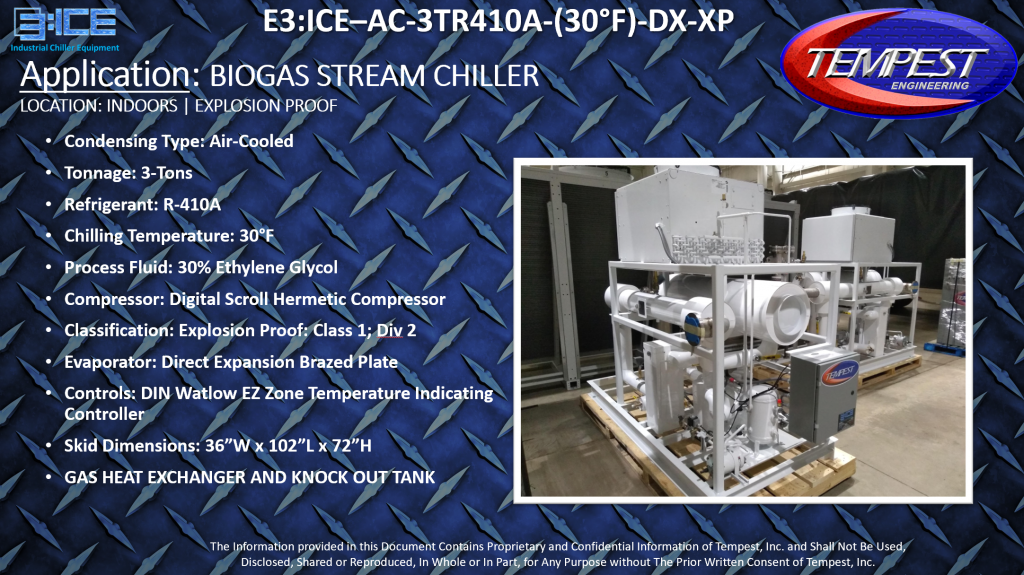

6.8-TON WATER-COOLED, EXPLOSION PROOF, EXTRACTION CHILLER

Condensing Type: Water CooledTonnage: 6.8-TonsRefrigerant: R-507Chilling Temperature: -50°FDesign HTF Fluid: Dynalene HC-50Compressor: Economized two-stage reciprocating

700-TON WATER-COOLED INDUSTRIAL AMMONIA CHILLER

Condensing Type: Water-CooledTonnage: 700-TonsRefrigerant: R-717 (Ammonia)Chilling Temperature: 32°F Saturated SuctionProcess Fluid: WaterCompressor: Twin Screw MotorsClassification: Explosion Proof: Class 1; Div 2Evaporator: Flooded Carbon Steel Shell & TubeElectrical: Pre Wired Electrical; Pre Wired

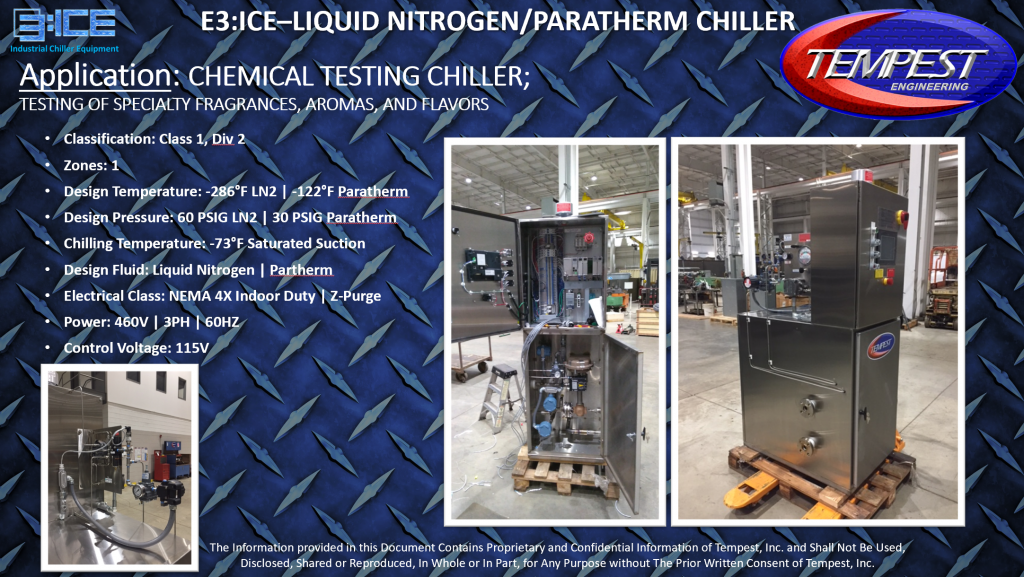

LIQUID NITROGEN & PARATHERM EXPLOSION PROOF CHEMICAL TESTING CHILLER

Classification: Class 1, Div 2Zones: 1Design Temperature: -286°F LN2 | -122°F ParathermDesign Pressure: 60 PSIG LN2 | 30 PSIG ParathermChilling Temperature: -73°F Saturated SuctionDesign Fluid: Liquid Nitrogen | ParthermElectrical Class: NEMA 4X Indoor Duty | Z-PurgePower: 460V | 3PH | 60HZControl Voltage: 115V

30-TON (35°F EVAP COOLING) AIR-COOLED INDUSTRIAL CONTAINERIZED CHILLER

Condensing Type: Air-CooledTonnage: 30-TonsRefrigerant: R-134AChilling Temperature: 35°F Saturated SuctionProcess Fluid: 35% Propylene GlycolCompressor: Semi Hermetic Compact ScrewClassification: Explosion Proof: Class 1; Div 2Evaporator: Direct Expansion Shell & TubeElectrical: NEMA 4 Enclosure with Allen Bradley Compact Logix PLC

250-TON (-32°F EVAP COOLING) WATER-COOLED INDUSTRIAL AMMONIA CHILLER

Condensing Type: Water-CooledTonnage: 250-TonsRefrigerant: R-717 (Ammonia)Chilling Temperature: -32°F Saturated SuctionProcess Fluid: 50% Methanol/WaterCompressors: Two (2) Open Drive Screw MotorsClassification: Explosion Proof: Class 1; Div 2 Group DEvaporator: Direct Flooded Carbon Steel Shell & TubeElectrical: Vilter Vision 20/20