LACKING INDOOR FLOOR SPACE OR HAVE SEVERE SPACE CONSTRAINTS? CONSIDER A TEMPEST CONTAINERIZED SYSTEM

CONTAINER CHARACTERISTICS

USA SOURCED AND PURCHASED

SIZES FROM: 20FT TO 50FT

DOOR ENTRY, LIGHTING, FREEZE PROTECTION, VENTILATION SFI RECEPTACLE

SINGLE POINT ELECTRICAL CONNECTION, ALARMS, SENSORS, FLOOR DRAINS

7.2-TON (-52°F EVAP COOLING) AIR-COOLED CHILLER & 24kW (230°F HEATING) TCU

COOL

Chilling Temperature: -52°F Saturated Suction

Capacity: 7.2-Tons

Refrigerant: R-507

Process Fluid: Dynalene HC-50

Electrical Class: NEMA 12 Indoor Duty

Compressor: 2 Stage Screw

Condenser: Air Cooled

Economizer: Direct Expansion Brazed Plate

HEAT

Heating Temperature: 230°F

Capacity: 48kW – Low Watt Density Electric Heater

Pump: Centrifugal rated for 30 GPM

Tank: 80 Gallon Nominal | 60 Gallon Operating

Electrical: NEMA 12 Enclosure

Controller: Allen Bradley Compact Logix PLC

30-TON (35°F EVAP COOLING) AIR-COOLED INDUSTRIAL CONTAINERIZED CHILLER

Condensing Type: Air-Cooled

Tonnage: 30-Tons

Refrigerant: R-134A

Chilling Temperature: 35°F Saturated Suction

Process Fluid: 35% Propylene Glycol

Compressor: Semi Hermetic Compact Screw

Classification: Explosion Proof: Class 1; Div 2

Evaporator: Direct Expansion Shell & Tube

Electrical: NEMA 4 Enclosure with Allen Bradley Compact Logix PLC

55-TON (-73°F EVAP) AIR-COOLED, JET ENGINE TESTING CASCADE CHILLER

Condensing Type: Air-Cooled

Tonnage: 55-Tons

Refrigerant: R-507A | R-508B (CASCADE CHILLER)

Chilling Temperature: -73°F Saturated Suction

Design Fluid: Dynalene MV

Compressor: Low Side (1) Semi-Hermetic Screw | High Side (2) Semi-Hermetic Screw

Evaporator: Brazed Plate Direct Expansion

Controls: Allen Bradley CompactLogix PLC

100-TON (-40°F EVAP) EVAPORATIVE-COOLED SPIRAL FREEZER CHILLER IN CONTAINER

Condensing Type: Evaporative-Cooled

Tonnage: 100-Tons

Refrigerant: R-717 (Ammonia)

Chilling Temperature: -40°F Saturated Suction

Compressor: One (1) Open Drive Screw

Evaporator: Direct Expansion Brazed Plate

Controls: Mycom Mypro Touch Microprocessor

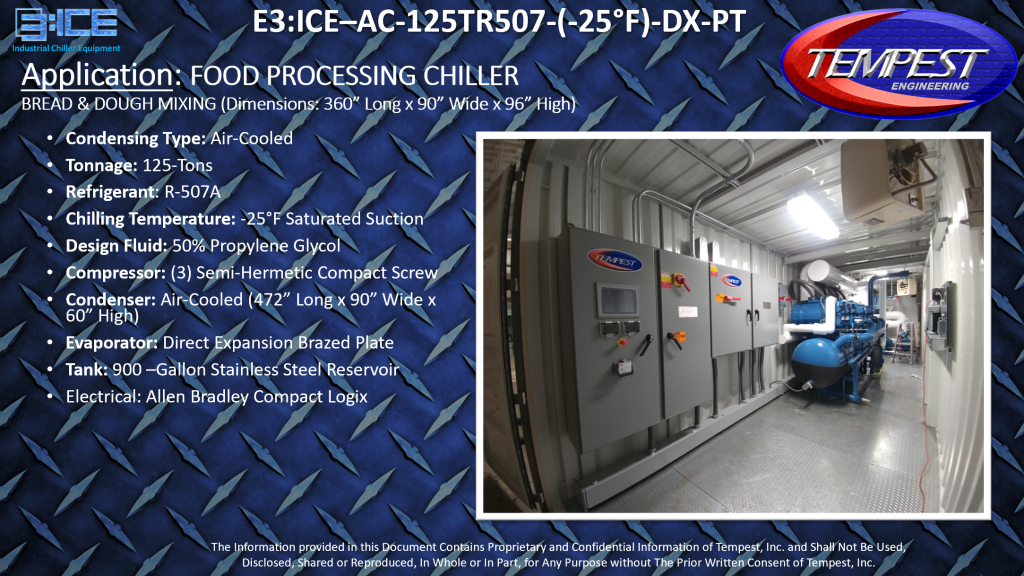

125-TON (-25°F EVAP) AIR-COOLED FOOD PROCESSING CHILLER WITH PUMP & TANK

Condensing Type: Air-Cooled

Tonnage: 125-Tons

Refrigerant: R-507A

Chilling Temperature: -25°F Saturated Suction

Design Fluid: 50% Propylene Glycol

Compressor: (3) Semi-Hermetic Compact Screw

Condenser: Air-Cooled (472” Long x 90” Wide x 60” High)

Evaporator: Direct Expansion Brazed Plate

Tank: 900 –Gallon Stainless Steel Reservoir

Electrical: Allen Bradley Compact Logix